Miniumum environmental impact

BOXBAY implements an autonomous, eco-friendly and sustainable solution which sets a whole series of new standards. The high-bay storage system fulfills a wide range of requirements and has been designed with much responsibility and consideration for the people who work in the ports or live in neighborhood of ports. BOXBAY is an example, especially for future generations, that shows that economic efficiency and sustainability are no contradiction but that the two complement each other very well – if done in the right way.

- Small terminal footprint & outstanding sustainability

- No local CO2 emission; with green energy supply even ZERO CO2

- High energy efficiency

- Fully electrical driven with power regeneration

- Energy saving operations with advanced controls

- Energy recuperation

- Solar panels on roof supply energy for operation

- In sunny regions solar energy is sufficient for self-supply of complete HBS

- Better public acceptance in urban environments

- Green wall cladding possible

- Few pedestrians in high-bay storage, reefer checkers, R&M crews

- No light pollution to nearby residential areas, no yard lighting required, only for reefer and R&M

- Minimal noise pollution (urban applications)

- High sustainability by all electrified equipment and power regeneration

- Multi trailer trucks handling without reversing (safety, space)

- Traffic segregation quayside and landside traffic

- Reduction of manned equipment under crane

- Remote controlled handoff on landside, better working environment for operator

- No container toppling, weather snow and wind proof storage

- Containers out of the sun (better for reefers)

- Fire fighting applications in ceiling or dedicated equipment

Smart

The world's leading ports are already highly digitalized. All information, such as the arrival time of the ships, freight details, and other data, is available at all times. However, the real problem facing ports is the lack of interfaces to enable the full digitalization of all processes. Today, BOXBAY is already bringing to life the vision of the "smart port", i.e. an intelligent, holistically connected port, by integrating the Internet of Things, big data, and artificial intelligence.

- Highly reliable and performant total automation system from Level 0 to Level 3

- Automation concept is single source delivery

- HBS digitalization package mainly comprises:

- Energy distribution and management

- Highly efficient drive systems

- Control and visualization

- Warehouse management system (HBS TOS)

- Business Intelligence module

- Works with any TOS

The digital basis of the fully automated BOXBAY system is the warehouse management system. The system knows exactly where each container is located, either in the high-bay storage or in the recirculation process. The information is clearly visualized – right up to 3D displays – on monitors or mobile terminal devices. As a rule, manual interventions in BOXBAY's fully automatic logistics processes are not necessary. This not only enhances efficiency but also occupational safety in the terminals. Conventional logistics automation can be predictively supplemented with state-of-the-art 4.0 solutions.

In the next expansion stage, the system can be equipped with autonomous processes that can display the container contents between sender and receiver in a fully digital way. That is why a system such as BOXBAY is a basic prerequisite for the autonomous port logistics of the future. The system handles freight forwarding orders flexibly and independently. Time-consuming transfers are eliminated, the containers are immediately ready at the transfer points in the ideal, specified order, so that they can be loaded onto trucks, trains, or ships.

Fast

BOXBAY is a disruptive technology that opens up new opportunities for container port operators, enabling them to run their terminals successfully in an economically and environmentally sustainable manner. BOXBAY's approach is to concentrate more storage space on the same surface area, resulting in greater efficiency and environmental compatibility.

- Direct container access at any time: each container is stored in an individual compartment

- 100 % utilization is possible (vs. max. 70- 80 % in conventional yards)

- Elimination of all unproductive moves

- No shuffling or housekeeping (vs. 30-60 % in conventional yards)

- Performance is independent from utilization and thus predictable

- Late runners, roll overs have no performance impact

- Truck turn around time well under 30 min

Many ports simply lack the space needed to keep up with the growth in global logistics. The construction of new ports is challenging from an economic and ecological perspective. The solution would be to expand ports around the world and thus create more storage capacity. However, this is only possible in rare cases. The limitations are many and varied. If it cannot be extended outwards, then it has to go up vertically. Here too, existing methods for exploiting the potential of seaports have now been exhausted.

That is why new approaches are needed for the "port of the future". Optimizing decades-old concepts is not the answer to these complex challenges. With BOXBAY we are be able to create more space for containers both in seaports and inland ports on the same surface area as before. This would not only solve the acute problem we are currently experiencing, but also prevent similar negative disruptions in the movement of goods by creating new free space for logistics chains and port operators.

Small terminal footprint

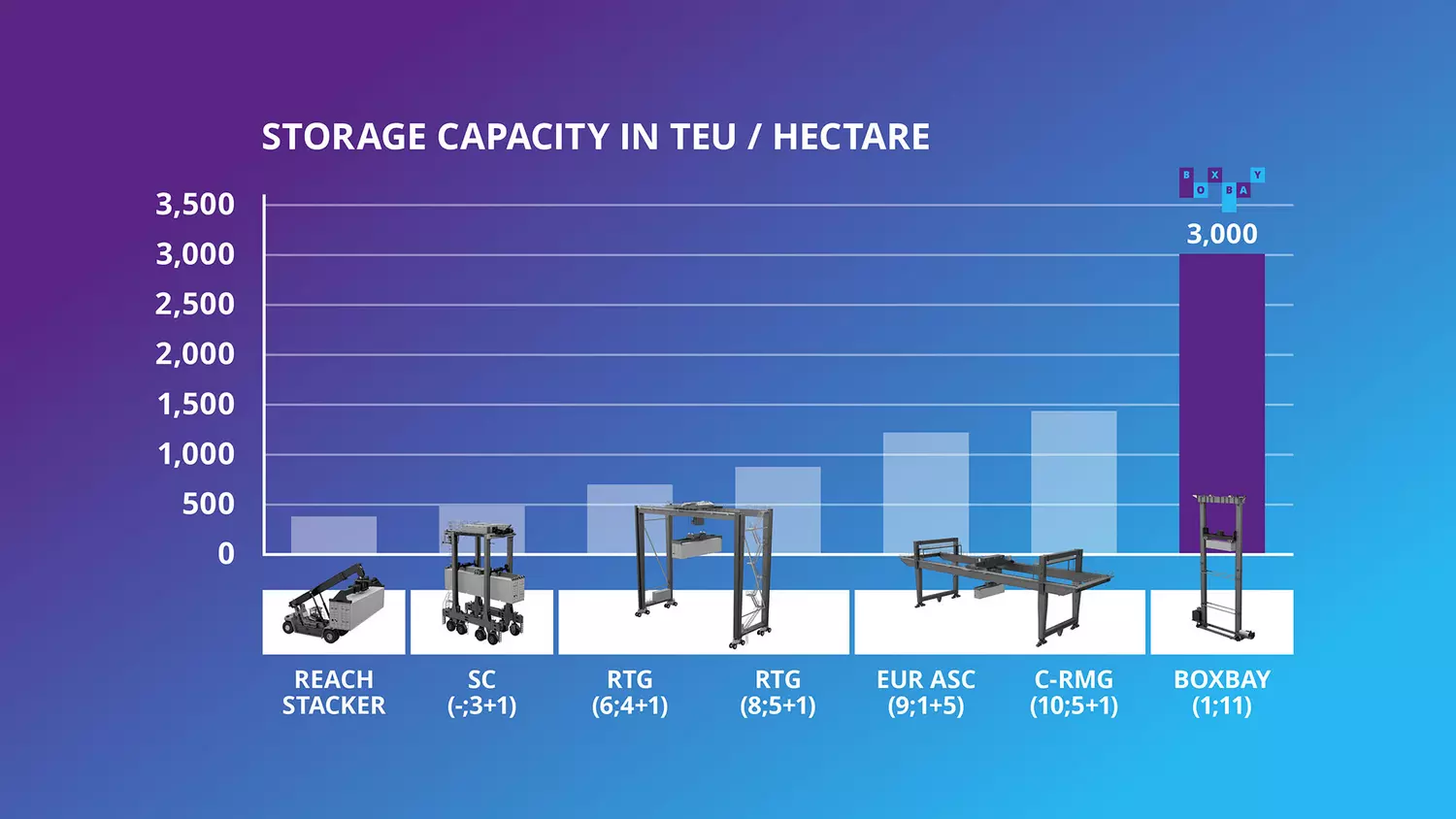

A major advantage of BOXBAY compared to conventional storage systems is its tremendously high concentration of storage space on the same surface area. With BOXBAY, the space required for the same storage capacity is slashed to around one quarter. BOXBAY allows terminal operators a more sustainable use of the limited space in ports. The high-bay storage enables capacity increases without the need of extra land. Land reclamation, which is very often the only way to expand existing container terminals, can be avoided with BOXBAY – and consequently also the risk of affecting the delicate eco systems in seas.

Effective maximum Storage Capacity

[TEU per hectare]

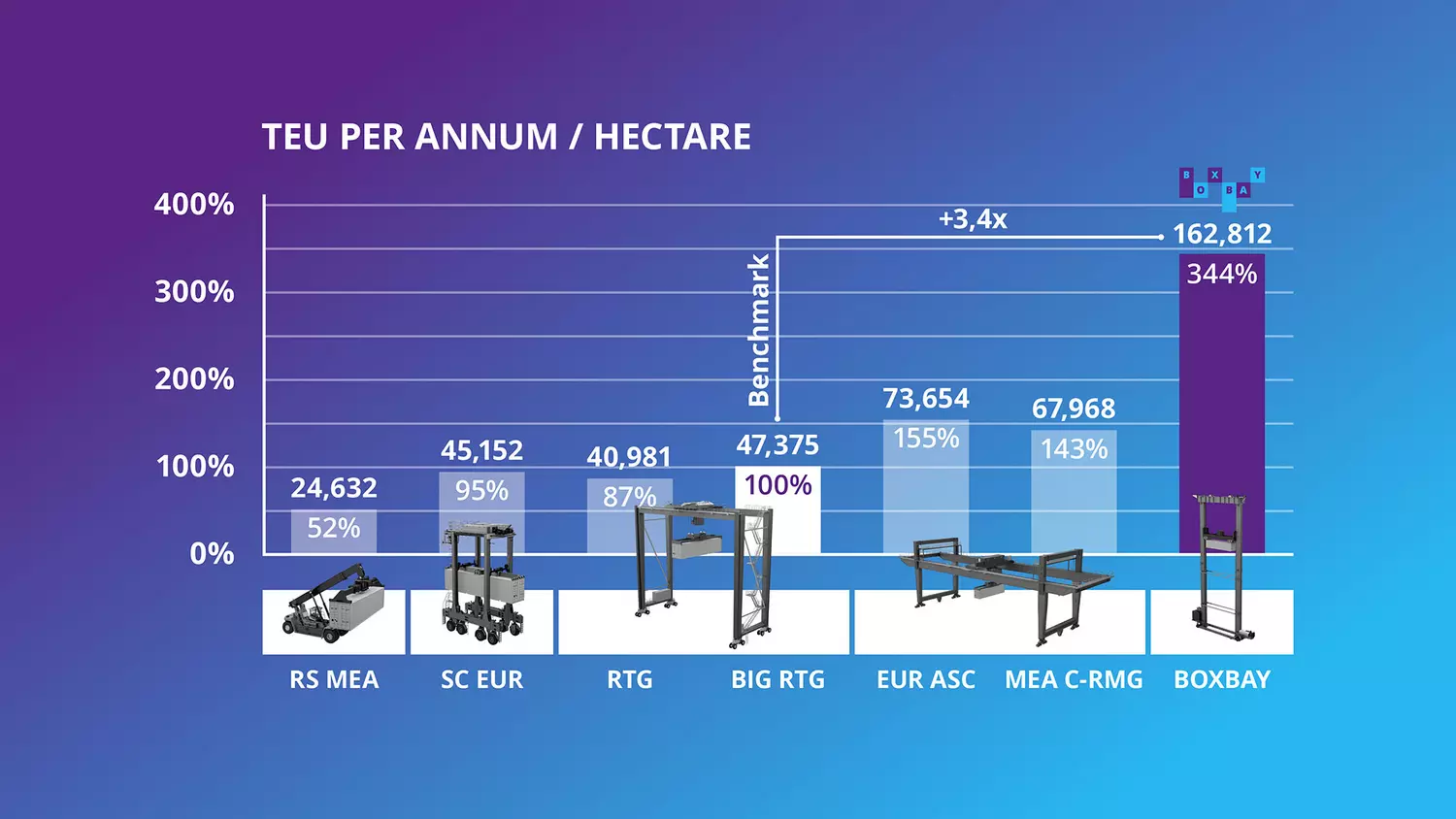

The storage capacity of a container terminal is tripled using the same surface area. Only one third of the floor space in a container port is needed for the same number of containers. The quayside transshipment speed is up to 20% higher – thanks to fully automated and digitalized systems as well as direct access to each individual container at all times, which also increases throughput speeds in the warehouse. In conjunction with potentially CO2-free operation, BOXBAY is a world-leading innovation and a disruptive "game changer" in port logistics!

Yard Capacity of different modes compared to HBS

When designing a container warehouse, the right balance must be struck between two parameters above all: storage density and throughput. Basically, both are mutual opposites. This means that the throughput per unit of area needs to be optimized accordingly. Direct access to each container in the BOXBAY system separates the warehouse's throughput from its density – and enables higher throughput per unit of area. The diagram shows how many TEU per operating year can be achieved with one hectare of storage area.

Green

But BOXBAY does not focus exclusively on resources-saving and CO2-free processes, two central topics of current political and public discussion. The BOXBAY engineers have already taken the next step by also addressing land use, noise nuisance and light emissions – issues that severely affect people living in cities or in the neighborhood of ports.

- Small terminal footprint & outstanding sustainability

- No local CO2 emissions: with green energy supply even zero CO2

- High energy efficiency

- Fully electrically driven with power regeneration

- Solar power plant on roof

- Noise suppressed operation

- Lack of light pollution

- Better public acceptance in urban environments

- Green wall cladding possible

The fully automatic operation of BOXBAY requires no light, so disruptive light emissions no longer impair the quality of life of residents nearby. The same goes for noise protection. Thanks to the automation and drive technology, BOXBAY operates quietly. What's more, storage and retrieval operations are performed inside a building that is equipped with all-round wall cladding.

Vertical gardens or greenwalls offer economic, ecological, and social benefits. They help to purify the air, lower ambient temperatures, regulate heat, and promote biodiversity in towns and cities. The BOXBAY warehouse building can also be completely covered with greenwalls on selected sides.

High energy efficiency

The "smart port" of the future must also be a sustainable "green port". Here, too, BOXBAY is setting standards as an autonomous, environmentally friendly, and sustainable solution. In a nod to the generations to come, BOXBAY demonstrates that economic efficiency and sustainability do not contradict but rather complement each other.

No local CO2 emission

BOXBAY is operated entirely with electrical energy. If "green electricity" is used, the system can be operated without any CO2 emissions and is far more energy-efficient than conventional systems: BOXBAY uses state-of-the-art energy recuperation technology and can thus drastically minimize its energy consumption. BOXBAY does away with all unproductive reshuffling processes because it offers direct access to the containers.

The roof of the system can be equipped with a wide-area photovoltaic (PV) system which produces the electricity to operate the facility. The BOXBAY PV roof enables not only CO2-free but even CO2-positive operation of container terminals. There are many different options for using the surplus energy – from feeding it into the local grid, to supercooling for refrigerated containers, right up to hydrogen production.

Get in touch

Do you have any questions or need more information? Get in touch via the contact form or contact us directly by phone or email. We will respond promptly.