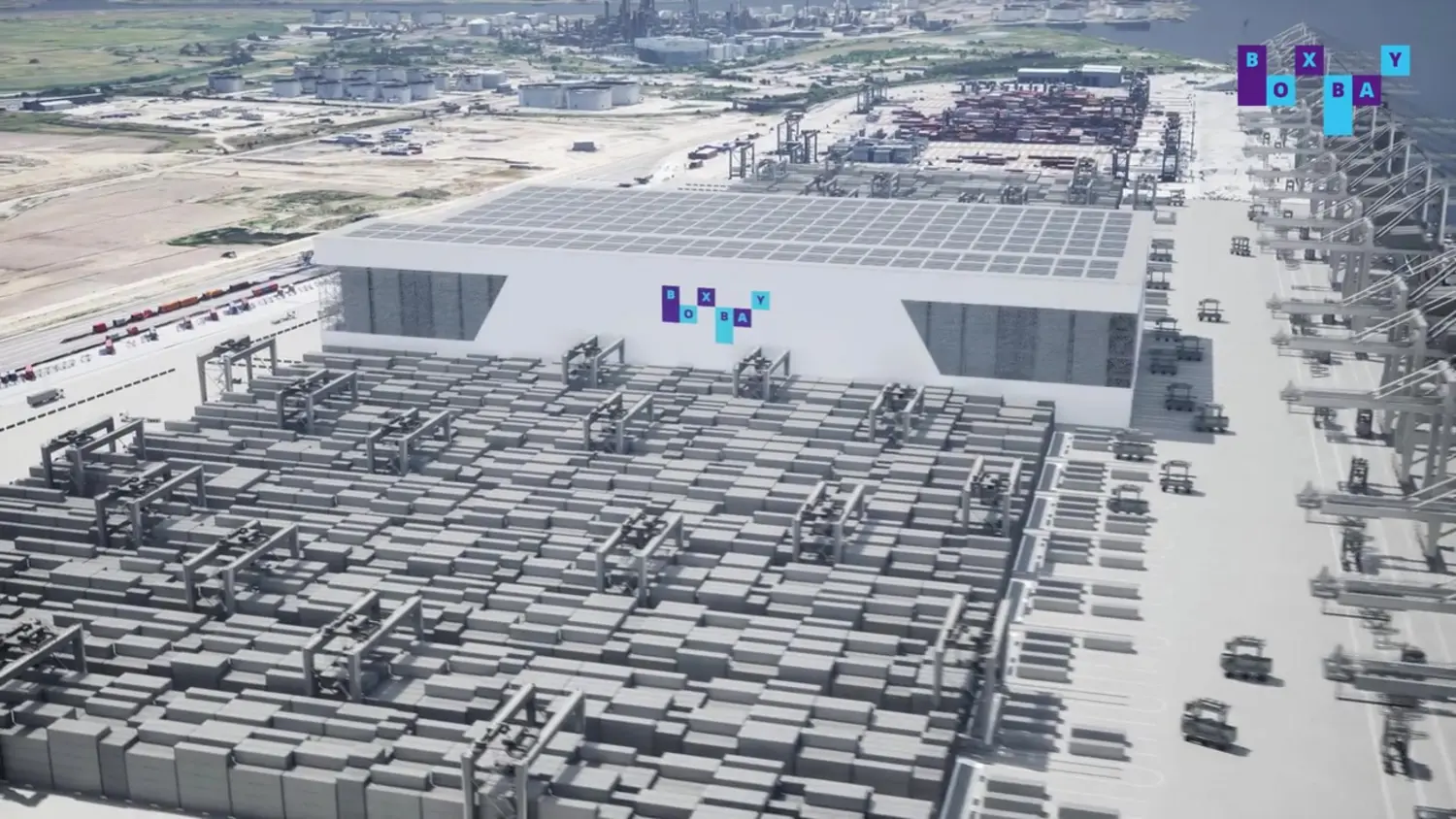

Revolutionizing Empty Container Stacking Efficiency

BOXBAY introduces an innovative High-bay storage system specifically designed to transform the stacking and handling of empty containers in terminal operations. With the ability to stack empty containers up to 16 tiers in a double-deep configuration, supported by a lighter and more efficient crane system, BOXBAY ensures optimal use of vertical space. The system offers flexible interfaces at each aisle end, making it compatible with all types of Internal Terminal Vehicles (ITVs) and enabling seamless integration with both manual and automated equipment. Additionally, the system’s smaller stack sizes allow for better separation into multiple categories, improving operational accuracy and efficiency.

BOXBAY sets a new benchmark in handling empty containers, combining advanced technology with intelligent design to deliver unmatched efficiency, flexibility, and space optimization for modern container operations.